RopeCon®System advantages.

Maintenance friendly

Small number of moving parts - Thanks to the straightforward, clean design and the small number of moving parts, the system requires less inspection and maintenance work.

Maintenance in the stations - Because the running wheels are attached to the belt, they keep passing through the stations where they can be inspected and maintained without a problem.

Environmentally friendly

Quiet operation - Low noise emissions due to plastic wheels which run on steel ropes.

Low dust emissions - Once the material has been loaded onto the belt it remains stationary. Dust emissions caused by material moving on the belt can therefore be reduced to a minimum.

High availability

The straightforward, clean design with only a limited number of moving parts helps to reduce the potential for defects while increasing availability.

Belt guidance with running wheels - No skewing of the belt even in crosswinds or with irregular load conditions.

Low operating costs

Low energy consumption - With its low friction coefficient the system requires less energy, which results in reduced operating costs.

Long service life of the belt - The material is stationary on the conveyor belt. This greatly reduces wear and tear on the conveyor belt.

Automatic operation - The number of operating personnel can thus be reduced.

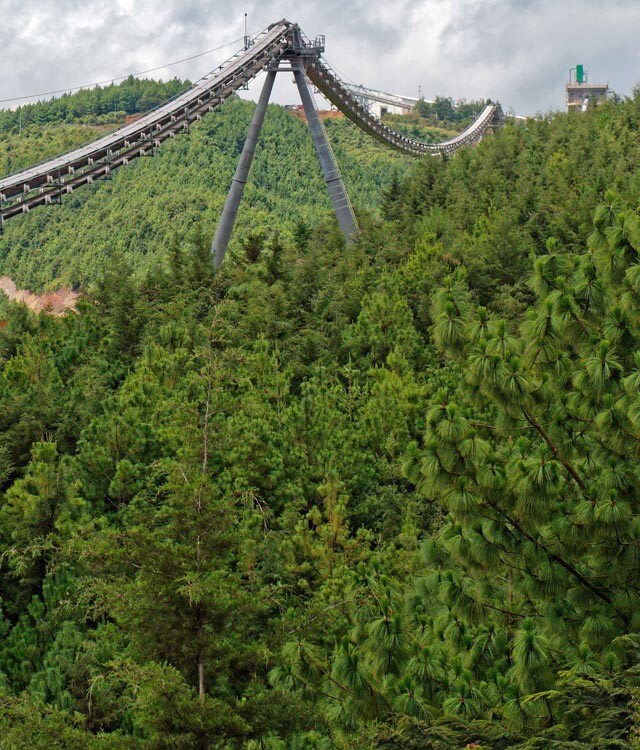

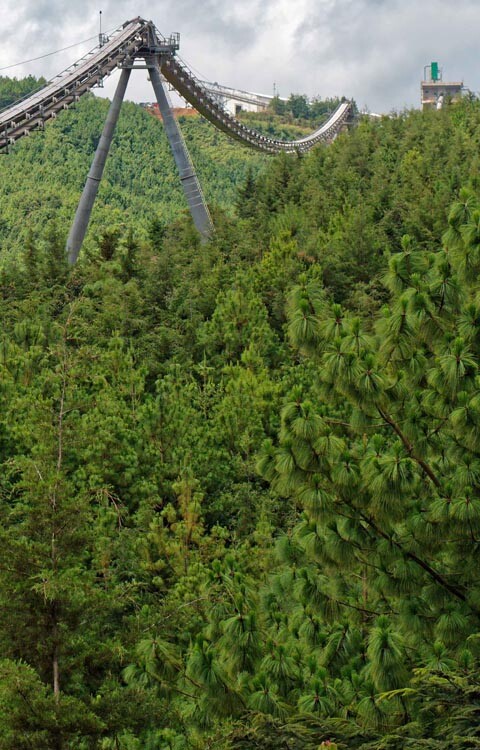

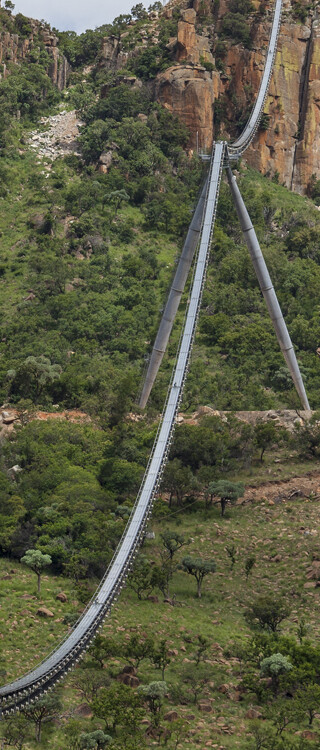

Ideal for challenging or sensitive terrain

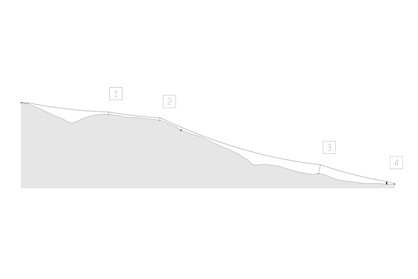

Long rope spans - The system crosses obstacles like rivers, buildings, ravines, or roads without a problem.

Line structure guided over towers - low space requirements on the ground, and no barrier for humans or animals.

Proven

Combination of two proven technologies: Belt conveyors and ropeways