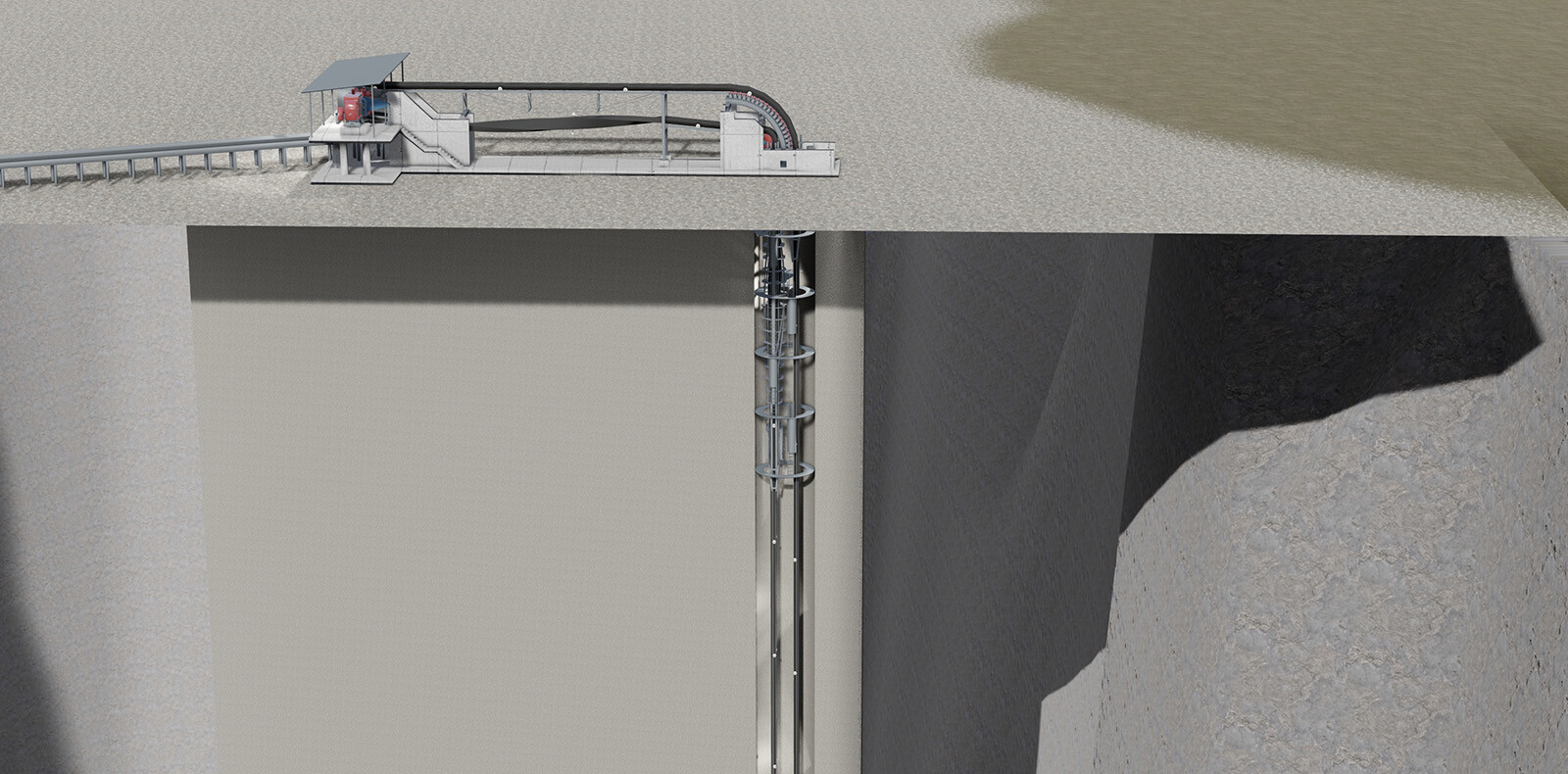

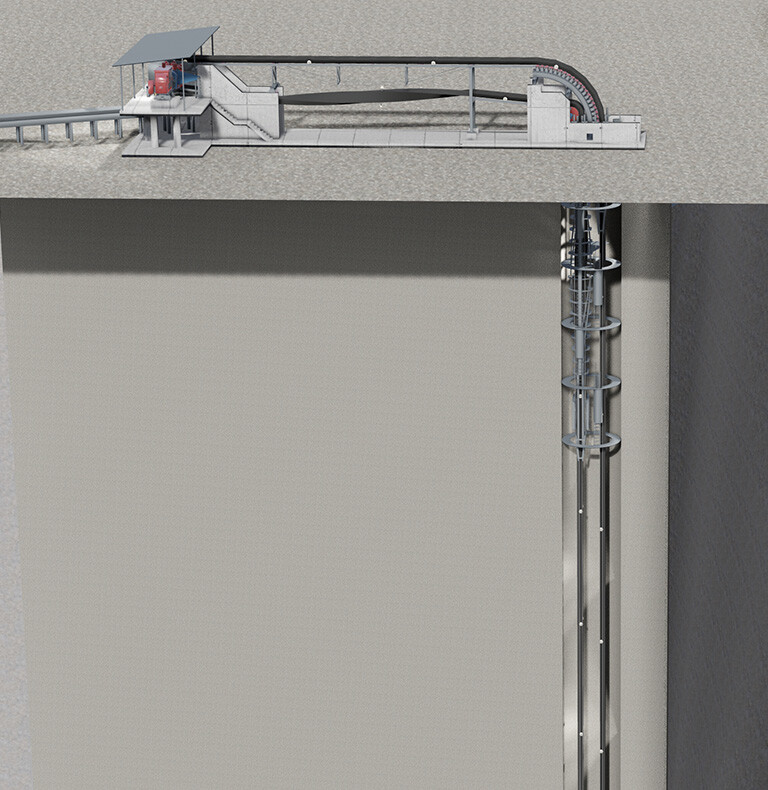

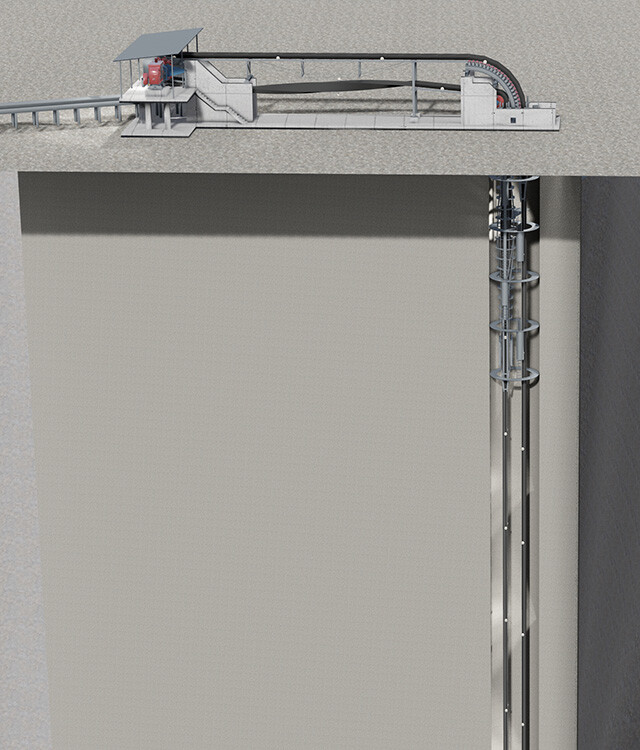

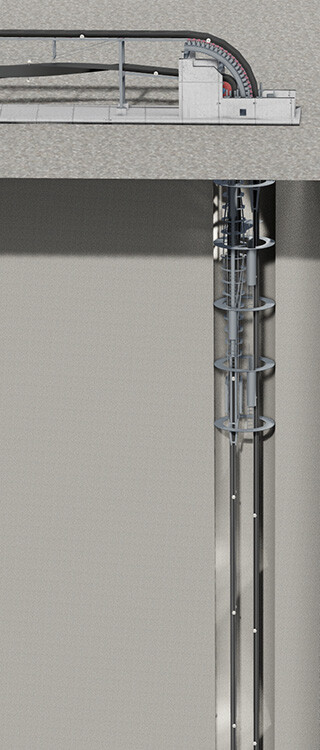

Vertical ConveyorVertical transport to surface via shafts.

Customer requirements:

Underground mining makes high demands on material transport, such as limited space as well as the necessity to avoid exhaust emissions and heat development, to name only some.

Our solution:

The Doppelmayr Vertical Shaft Conveyor opens up new material transport opportunities for underground mining and gives the chance to reduce the haul truck fleet and the exhaust emissions.

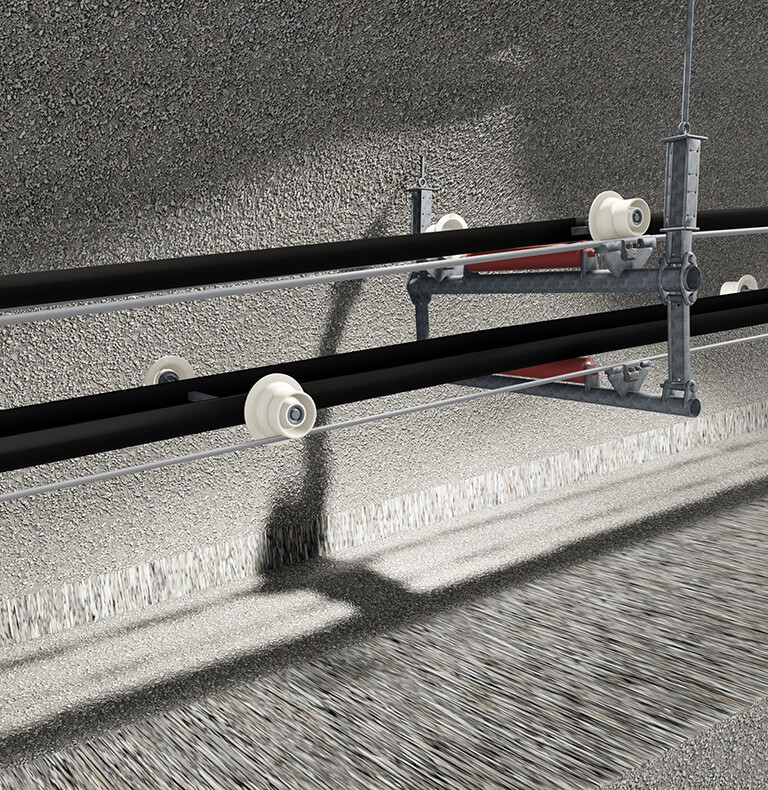

The novel concept adapts the proven RopeCon® system to the specific requirements of an underground application. In the loading station, the wheel sets run on guiding rails, which safely guide the belt into the shaft. Ropes in the shaft guide the belt at all times.

Maintenance is simple and cost effective, as all moving parts are mounted to the belt and will pass the terminals at regular intervals. Ropes and shaft are inspected by a camera system, which is attached to the belt. Access to the shaft is not required.

Re-use of existing ventilation shafts is possible. As the main drive is installed above ground, underground heat development is reduced.

| System | RopeCon® |

| Max. lump size | 150 mm |

| Vertical lift | 750* m |

| Conveying capacity | 2,000* t/h |

| Clear shaft diameter required | 3.5* m |

| *depending on material properties and operating conditions, see the following examples | |

| Example 1 | |

| Vertical lift | 700 m |

| Conveying capacity | 700 t/h |

| Example 2 | |

| Vertical lift | 600 m |

| Conveying capacity | 1,000 t/h |