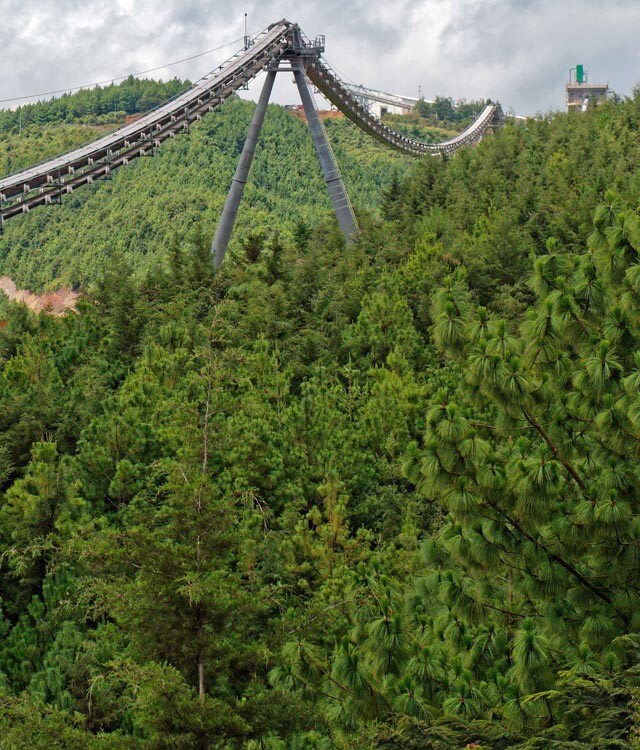

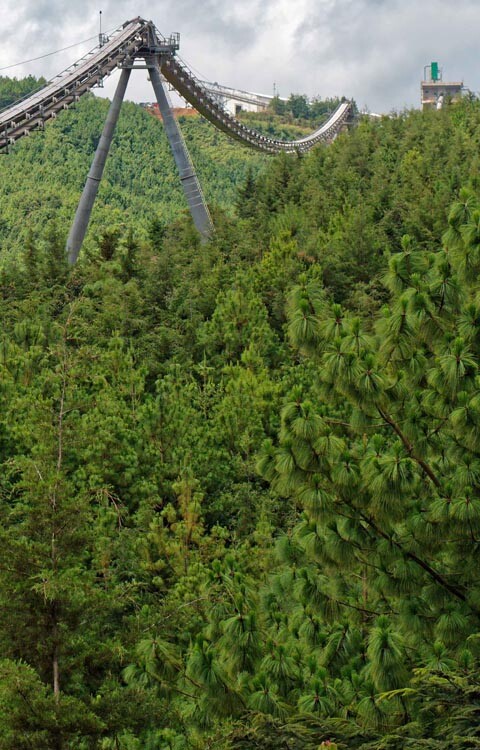

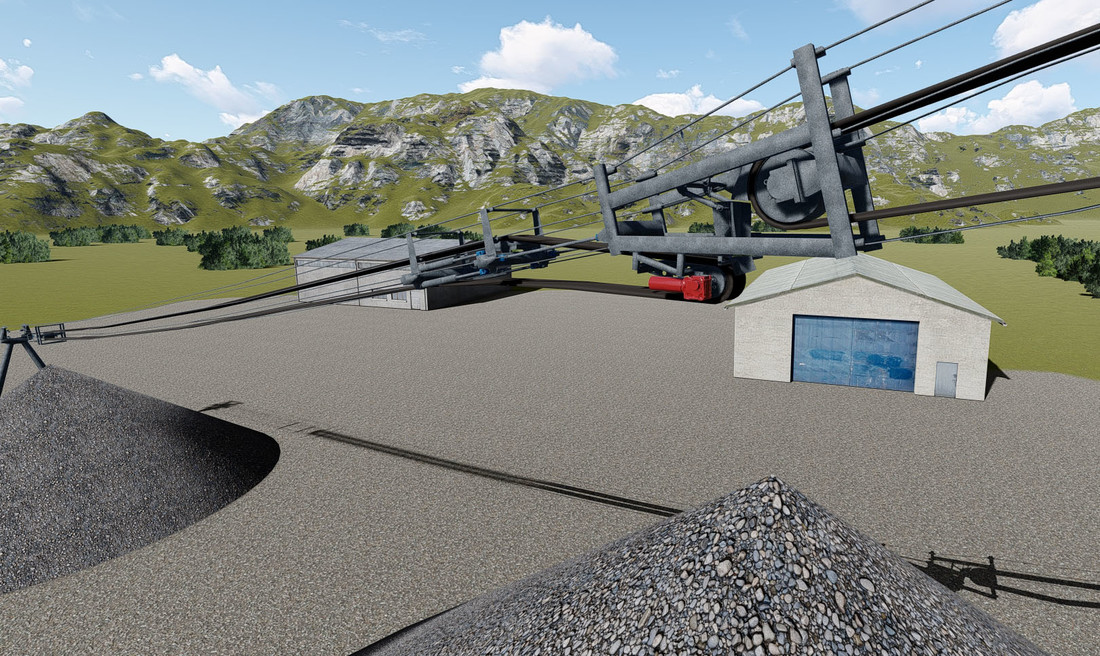

Two discharge points along the line.With just one transport system.

Customer requirements:

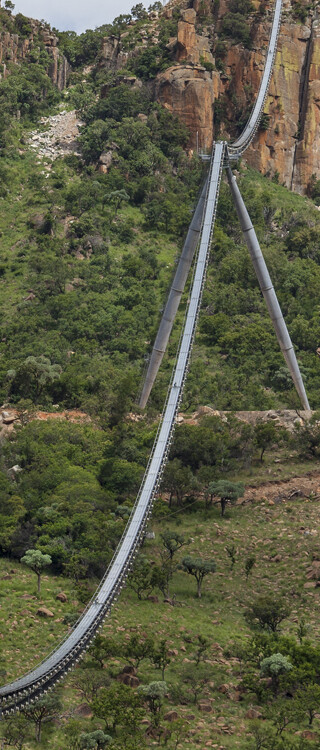

Every hour 1,000 tons of ore are transported from an existing open-pit mine to the silos at the processing plant. Trucks are currently used for that purpose. The customer is looking into alternative means of transport with the aim of reducing costs. The new system must transport the material over a distance of 1,350m and a vertical rise of approx. 125m while being sufficiently flexible to permit unloading of the material onto two different stockpiles.

Our solution:

RopeCon® can meet the customer's requirements and at the same time help to reduce transportation costs. With this solution only a few trucks are still required to take the material from the different extraction sites to the RopeCon® loading point. Once the material is on the conveyor belt it will be conveyed out of the pit in a straight line. Upon arriving at the top, it is unloaded via a twin chute either onto the first stockpile or onto a second RopeCon® belt which is mounted on the same track rope structure. The second stockpile is located at the discharge point of the second belt. The twin chute allows for an easy changeover from one stockpile to the other.