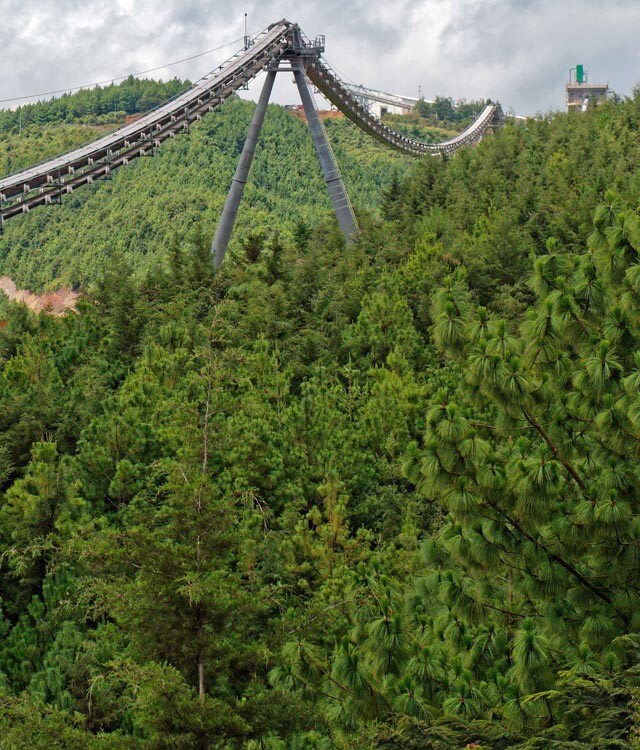

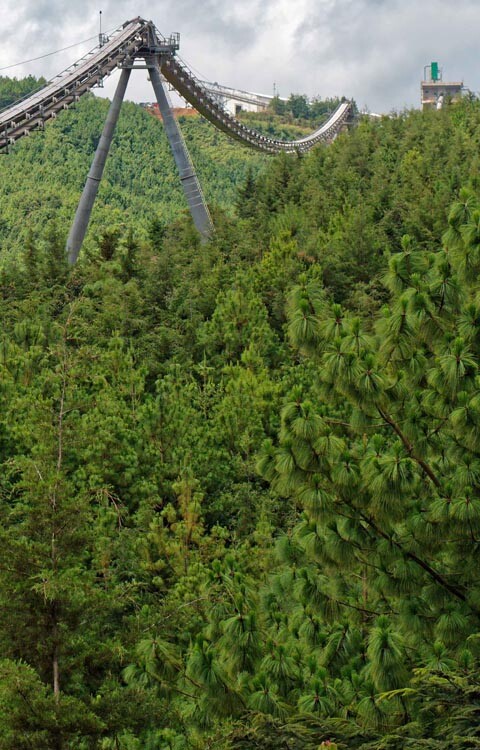

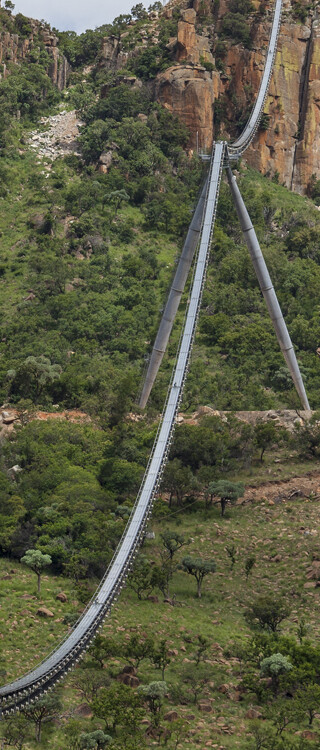

RopeCon® connects mine with crusher in the valley.Installation with steep gradient in a harsh climate.

Customer requirements:

The customer wants to expand an existing mine. The mining area is approx. 400m higher up than the crusher, and a conveying system is required which is suited to transport relatively large lump sizes of up to approx. 500mm. The aim is to avoid having to build a new crusher in the immediate vicinity of the mine. The harsh climate with snow and strong wind poses further challenges. Approx. 400t of ore must be transported into the valley every hour for further processing.

Our solution:

The steep terrain and the relatively large lump size suggest using a RopeCon®. The system will be able to cover the complete distance with just three tower structures. Inclines of almost 50% are no problem for a RopeCon® either. The structure of the conveyor belt with its wheel sets mounted at regular intervals provides additional stability to the material on the belt, so that RopeCon® is suited for steeper inclines than conventional conveyors. Due to the great difference in elevation between the mine on the mountain and the crusher in the valley the system can even generate energy from braking actions which can be fed back into the grid.