Transporting material in two directions with one transport system.Efficient link between new plant and port.

Customer requirements:

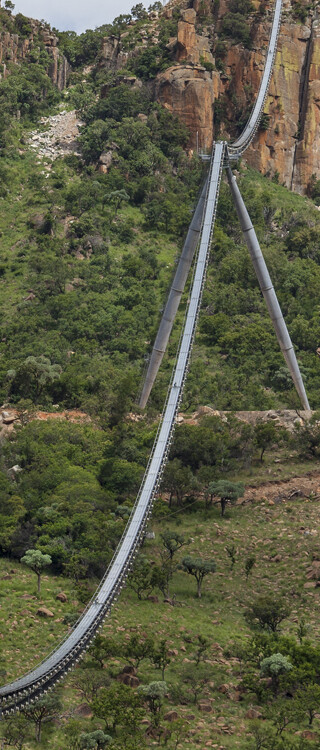

The customer plans to build a new cement plant in the vicinity of the limestone quarry. This is the starting point from where clinker is to be transported to the port, located approx. 11km away as the crow flies. If you were to follow the road, the distance would increase by some 6km, and the road is rather steep in the vicinity of the quarry. Some 1,500 tons of material must be transported to the sea every hour.

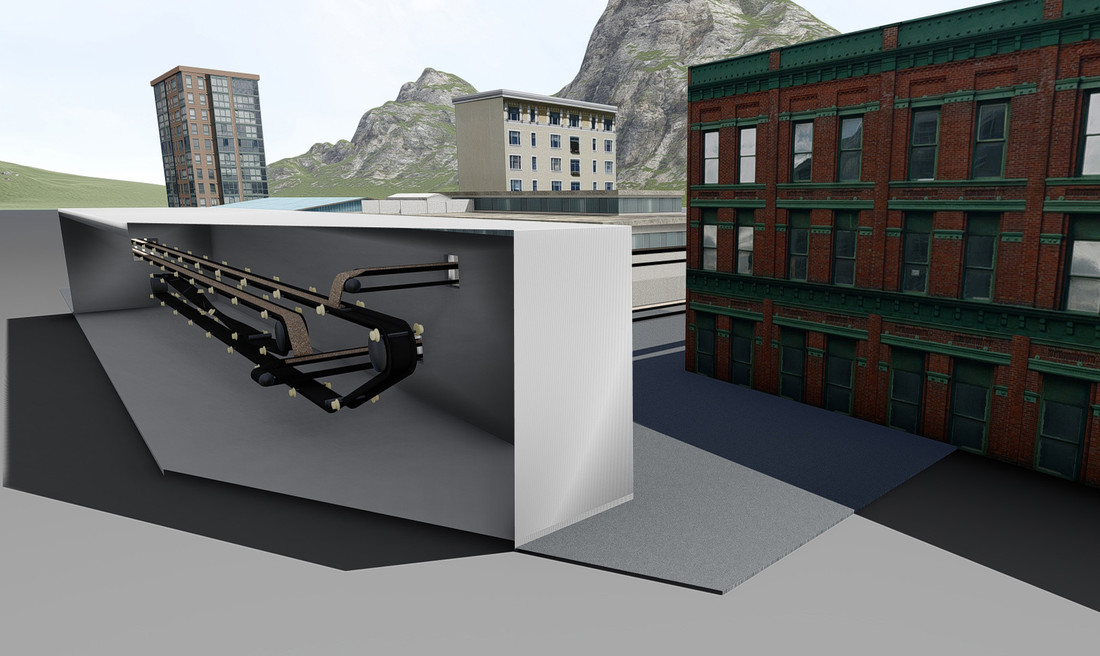

And that is not all: The cement plant is run on coal. The coal is delivered to the port. To meet the fuel demands of the cement plant, up to 1,500 tons of coal must be brought to the plant every hour.

Our solution:

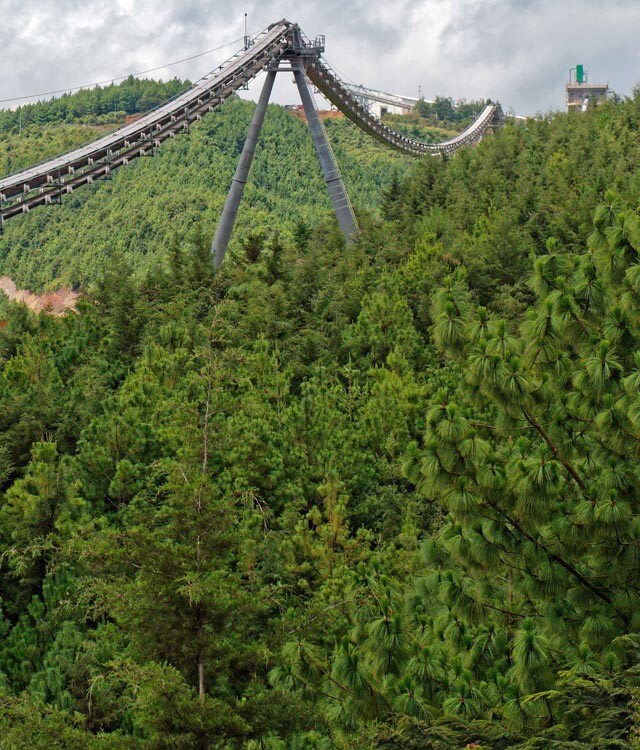

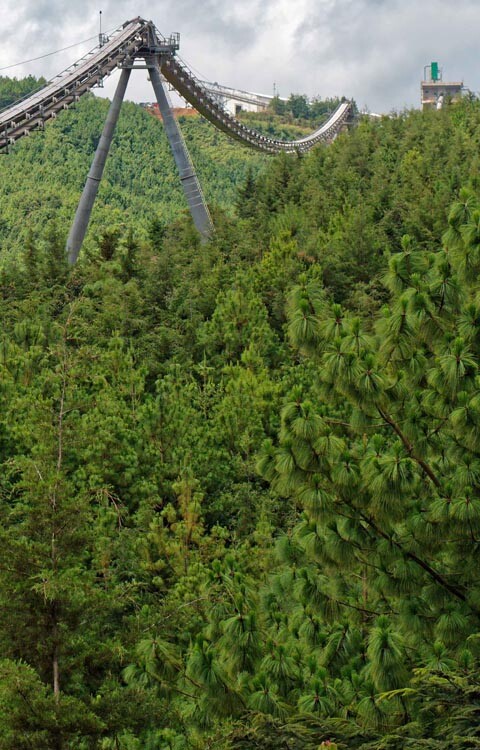

We recommend to use RopeCon® as a solution. Given the topographic situation the system will be designed in two sections, each with a length of approx. 5.5km. With its straight line, RopeCon® makes it possible to reduce the conveying length. A change of the conveying direction will take place at the transfer point between section 1 and section 2. The conveyor will cross several roads, power and telephone lines, agricultural land and forests. With RopeCon®, only one system is required for bi-directional transport: both the coal and the clinker can be transported with one belt, one on the top belt, and the other on the bottom belt. The costs for one complete system can thus be saved.